More than just GPS tracking, our Fleet Maintenance Software will bring your business unparalleled benefits. Linxio has the ability to capture your vehicle information, manage scheduled maintenance workloads, schedule preventative maintenance and vehicle inspections with digital forms.

Diagnostics

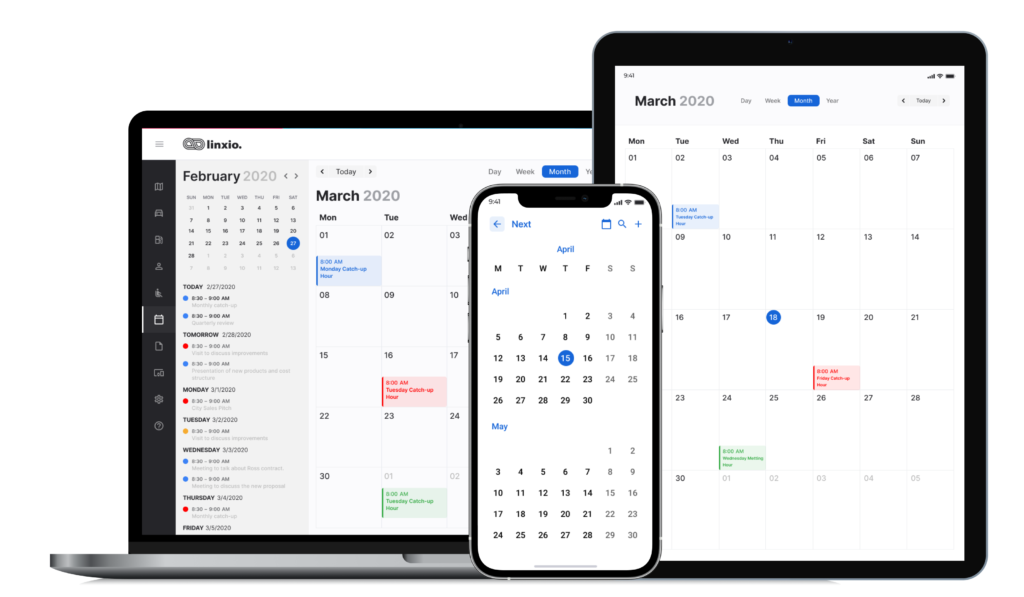

Scheduling

Inspections

Custom Alerts

BHP

NSW Health

Comlink

Hertz

Category5

South32

John Holland

Stay on top of your fleet’s maintenance items such as oil changes, wheel alignments, brakes and more with the integrated fleet management system. Manage reminders with Service schedules and Linxio fleet maintenance system will remind you when service is due, helping you increase efficiency & maximise vehicle up-time.

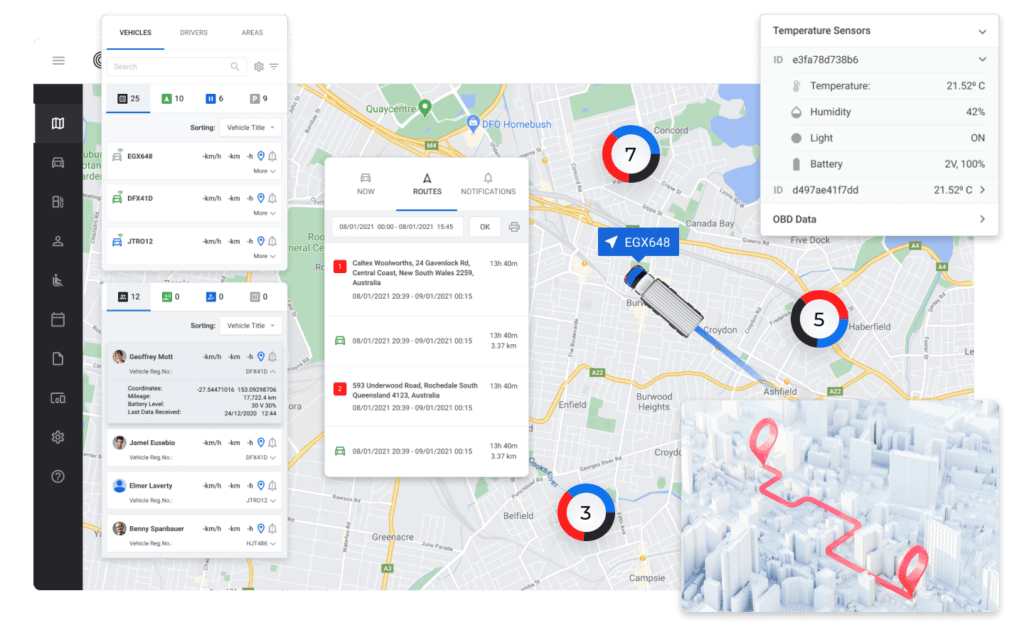

INCREASED VISIBILITY

With Linxio Fleet Maintenance Software you can pull engine fault codes or analyse other data to find out which cars need the most help. This solution would allow fleet maintenance departments to focus on priority vehicles and move from scheduled servicing to preventative maintenance, which would increase the productivity of your fleet vehicles.

STREAMLINED MAINTENANCE

The efficiency and condition of the vehicle is affected by how it is driven. Increased wear and tear on your assets can impact business profitability in the long run. You can proactively intervene with our driver behaviour scorecards when it comes too unsafe or risky drivers with our fleet maintenance software.

INCREASED VISIBILITY

Think of Linxio as the brains behind your fleet operations. If you want to make better decisions for your organization, you need to centralize all your data, integrate third-party solutions (like GPS Trackers, and Fuel Cards) and use data science. Control costs with real-time metrics and gain total control of your fleet maintenance costs.

• Fault code monitoring

• Paperless Inspections

• Usage-based maintenance

• Wireless IoT Sensors

• Live temperature alerts

• Lifetime historical logs

• Distracted driving detection

• In-cab coaching alerts

• Automatic incident upload

• Route optimisation

• Proof of delivery (POD's)

• Dispatch to Driver App

• Driver & vehicle documents

• Centralized record-keeping

• Expiration alerts and report

• FTC, FBT, ATO certified

• Works with iOS or Android

• Centralized visibility

Preventative and predictive maintenance are two types of fleet maintenance that are commonly used. Preventative maintenance is routine maintenance performed on a vehicle to avoid breakdowns. When signs show that prompt intervention will prevent breakdowns and costly repairs, predictive maintenance is carried out. Fleets can keep more of their vehicles if they use both of these strategies.

Linxio's fleet maintenance software is designed to help fleet managers identify and resolve engine issues quickly and efficiently. The software provides critical engine data that can be used to diagnose problems and prioritize repairs. By focusing on predictive engine health, fleet managers can save time and money.

Fleet maintenance software can offer a number of benefits to fleet managers and operators. Perhaps most importantly, fleet maintenance software can help improve fleet uptime and prevent unexpected downtime due to maintenance issues. Additionally, fleet maintenance software can help optimize fleet maintenance costs by providing tools for managing inventory, scheduling preventive maintenance, and generating cost reports.

Fleet maintenance software can help fleet managers improve fleet safety in a number of ways. By monitoring engine data and diagnostics, fleet managers can identify potential issues before they become problems. This helps to avoid breakdowns and accidents, keeping vehicles on the road and drivers safe.

Pricing depends on a few things, such as your business requirements, fleet size, whether you purchase hardware outright, or go on a rental plan, etc.

The best way to get all the information on pricing is to complete the form above for an obligation free quote

There are a few key steps to setting up an effective fleet maintenance program:

1. Establish what type of maintenance is required for each vehicle in your fleet. This will vary depending on the make, model and age of the vehicles.

2. Decide who will be responsible for carrying out the maintenance tasks. This could be an in-house team or an external provider.

3. Put together a schedule of when each maintenance task needs to be carried out. This should take into account things like mileage, usage patterns and the time of year.

4. Make sure you have the necessary tools and resources in place to carry out the maintenance tasks. This could include things like a workshop, diagnostic equipment and a stock of spare parts.

5. Keep records of all the maintenance tasks that have been carried out. This will help you to spot any trends or potential problems.

By following these steps, you can be sure that your fleet is in good hands and that it will be able to meet the demands of your business.

Our Company

Subscribe to our newsletter